We remain committed to delivering reliable and sustainable end-to-end solutions and offerings for our customers.

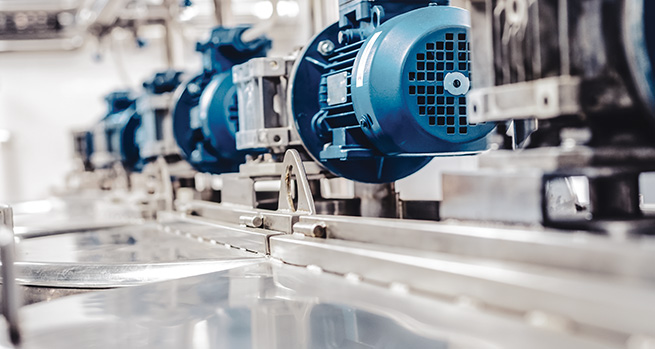

The Industrial division offers a wide range of product and service solutions for varied applications in the industrial sectors. Our portfolio of product offerings covers various designs of ball and roller bearings ranging from few millimeters of outer diameter extending up to a meter. Our products can be found in use in the sectors like railways, wind energy, two wheelers, heavy industries - steel, cement & mining, machine tools and robotics, off highway applications and many others.

Angular contact ball bearing

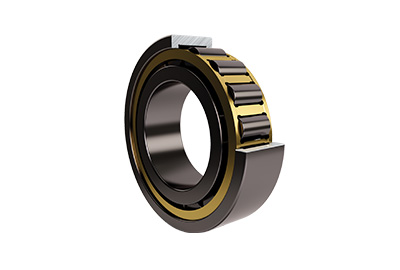

Cylindrical roller bearing with black oxidised coating

Cylindrical roller bearing with MPAX-cage

Double row tapered roller bearing

Spherical roller bearing with black coating

Tapered roller bearing with black oxidized

Two row tapered roller bearing with black oxidised coating

OPTIME C1

Revenue up 5.1% YoY

Schaeffler India Loyalty Index

Diameter of largest bearing refurbished

Sustainable solutions

Customers are demanding sustainable products and solutions that use fewer resources and will last longer.

Focus on renewable energy

India has set an ambitious target of deriving 50% of energy through renewable energy sources by 2030 and wind farms are expected to contribute ~100 GW from current 53 GW in this energy mix.

India’s focus on hydrogen

The Government of India is focusing on green hydrogen. The Interim Budget for 2024-25 allocated H600 crore for the National Green Hydrogen Mission, compared to the previous year’s budget of `297 crore.

Government policies

The government increased capital outlay to `11 trillion, and continued to provide impetus to ‘Make in India’ through allocations to PLI schemes.

Expansion of industrial production capacity

Expansion at Schaeffler India’s facility in Savli and Vadodara Gujarat, adds to the manufacturing capacity for small and medium-size products, further enhancing Schaeffler’s market competitiveness in the region. The expansion of the Savli plant’s production capacity is marked as a vital step towards driving localisation strategy and meeting the growing demands.

The facility enables us to add capacities of over 10,000 sq.m. of production space, to the existing state-of-the-art manufacturing plant. This enabled the manufacturing of spherical roller bearings (SRB) and spherical rollers, while also expanding the heat treatment capabilities. This will also help to cater to the market demand in the wind, heavy industries, and railway sectors.

With this expansion also comes an increase in employment opportunities. By 2025-2026, Schaeffler India expects the employee strength at the Savli plant to double, signifying the Company’s commitment to creating sustainable employment and fostering economic growth in the region. It also supports the country’s ‘Make In India’ call, and Schaeffler is proud to contribute towards this initiative.

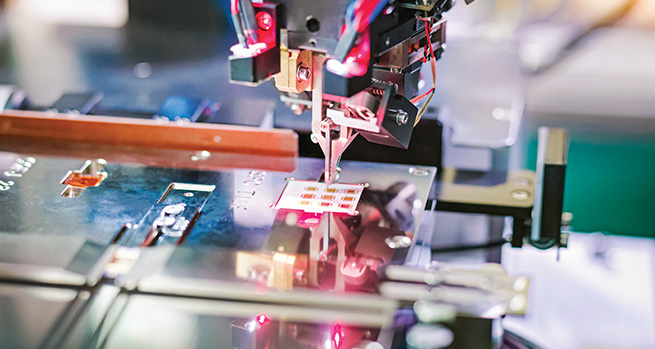

Application engineering and after sales support

At Schaeffler, our customers are central to everything we do. Our capable team of application engineers and technical services actively engage with customers to not just resolve issues at the customer place, but also help and enable them to improve their process performance. Be it in the critical mounting of a steel converter trunnion bearing or a large windmill main shaft bearing, we address the customer needs with their engineering support and use of advanced tools and equipment, thereby instilling a high level of confidence in our esteemed customers.

Customer challenge

One of the leading OEMs in the wind sector, faced a challenging situation of assembling bearings on the main shaft in horizontal direction owing to limitations from the size of the equipment and complexity of mounting.

Our approach

Having understood the nature of concern and applying our engineering expertise we could offer the customer a fail safe mounting solution in the horizontal axis that not only saved time but also associated costs. This reinforced our commitment to customer centricity, helping us further strengthening our relationship.

Our agility and resilience helped us to mitigate the headwinds during the year and supported our growth. The Industrial business grew 5.1% y-o-y to H25,478 mn this year. We made significant business wins in various sectors, solidifying our position as a reliable player in providing integrated solutions. Our consistent growth in our Lifetime Solutions business is a testimony to our clear focus on our digitization drive.

We are continuously adopting and employing new technologies through lean manufacturing practices, digitalisation, and renewable energy integration. Our manufacturing sites demonstrate the practice of reuse, recycle and reduce. We also believe that our distribution partners have been instrumental in our growth and we continue to invest in enhancing our channel network, competence and presence.

We continue to invest in India ramping up our manufacturing footprints, embrace innovation in a rapidly evolving industrial landscape and to accelerate the transition to a greener future.”

Seshan Iyer

Industrial