The Industrial division offers a wide portfolio of bearing solutions, ranging from high-speed and high-precision bearings with small diameters, to large-size bearings, several metres wide. Increasingly, the focus here is on smart products and connected technologies.

Key strengths and enablers

169

Distributors

Bringing in insulation-coated bearings

With increasing electrification, there is a higher chance of damage to the bearing. Our insulation-coated bearings are designed to prevent such damage, thereby helping our customers avoid huge losses. Currently, we are the only manufacturers, who have the capability to make these bearings in India. The product was launched last year and is being used mainly in metros and railways and has been seeing a sharp growth in demand.

Leading with Make in India

TAROL bearings are used in axle boxes for metro trains, as the bearing sits inside the axle box and the entire sub-system is to be supplied to the customers. It is a matter of immense pride that our solutions, which are completely Made in India, are today carrying the load in metro trains running in many cities across India and even in a few other continents.

Operating environment

India’s industrial landscape is changing with organisations looking for disruptive tools, which help them increase efficiency and reduce cost. Digitalisation is seeing active acceleration with rapid adoption of remote diagnostics and collaborative tools.

Our response

We continue to make investments in future technologies such as mechatronics and Industry 4.0, among others. We also have developed new automated lubrication solutions globally with plans to introduce them in India eventually.

Globally, an increasing number of companies are focusing on reducing their carbon footprint and opting for renewable energy. India is becoming a hub for wind turbine manufacturing, and the demand for large-size bearing has been increasing. Railways, which is one of the most carbon-efficient transports, especially for in-land freight, is also expected to see a significant demand uptick after a brief slowdown in tenders during the pandemic.

Our response

We are making significant investments in Savli to increase our localised manufacturing capacity for catering to the railway and wind sectors.

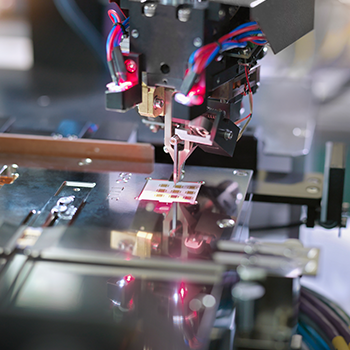

Delivering customer delight through our Quick Center in Maneja

We launched linear guide product from Schaeffler Global in India to meet the growing demand for industrial automation in the country. However, the product order intake was subpar despite the product receiving positive review from customers. This was due to long waiting period of 9-12 months for order delivery as we were importing the finished product. To minimise the lead time, we implemented ‘Make in India’ strategy by importing semi-finished product and locally assembling at our Maneja unit. This drastically reduced the lead time to 2-3 weeks and enabled customisation of product as per customers’ requirements. Consequently, we are able to successfully garner orders for linear motion guides.

Embracing digitalisation, driving change

With the government’s focus on developing high speed trains in India, meeting performance, reliability and safety standards of trains is gaining topmost priority. We are embracing digitalisation to enhance our core offering by opening up opportunities to check the health of the bearings, while its in motion. We are working on developing axle box bearings integrated with sensors, which can send digital feedback and be used to monitor the health and performance of the bearings.

Reviewing 2021

| Contribution to overall performance | 39%

Contribution to revenue |

| Performance highlights | 39%

Growth over 2020 |

| Customer metrics | 8.03

Schaeffler loyalty index |

New products introduced in the market

Angular Contact Ball

Bearing

CRB wo outer ring

DGBB OSD

Insulated coating DGBB1

Insulated Coating DGBB2

SRB

rollers

Tapered Roller

Bearing

Tarol2

TRB full component

HOUSING 2.2504

“After a tepid market last year, with the pandemic causing uncertainty and dampening overall industrial growth, we saw strong rebound this year. The momentum across the industrial segment remained strong, and we were able to capitalise on the same. We made significant business wins and further consolidated our leadership position in the relevant segments. Our revenue grew by 39% as compared to 2020, and 18.0% to 2019 levels.

We did see some pressure due to the rising raw material costs and supply challenges, especially for our imported products. We are increasingly trying to manufacture more products at our Indian plants, in line with our localisation strategy. This will continue to help us make our products available with the shortest possible lead time and increase our competitiveness.

Wind, machine tools, industrial automation, off-road, power transmission, and raw materials are seeing growth supported by favourable policies of the government and this augurs well for our business. We have seen strong traction across multiple sectors during the year and with continued demand and high consumer sentiments, we expect to see positive, long-term growth in these sectors. We are ready to capture the Indian growth story with our robust portfolio, technical and operational know-how, and ever-expanding capacity.”

Mr. Harsha Kadam

Managing Director & CEO,

President- Industrial

Our strategic focus