With prudent use of natural capital, we are constantly working towards minimising our environmental footprint. Our environmental approach is based on improving our existing processes and systems, and proactively adopting more efficient processes for new operations. Aligned with our group’s objectives and targets, we are in the process of creating a regional strategy to achieve our environmental commitment.

We are setting benchmarks for environment‑friendly manufacturing, adopting some of the most stringent regulations. Schaeffler India is not only compliant with all local regulations but is also one of the early adopters of the strict European guidelines for environmental protection Eco-Management and Audit Scheme (EMAS).

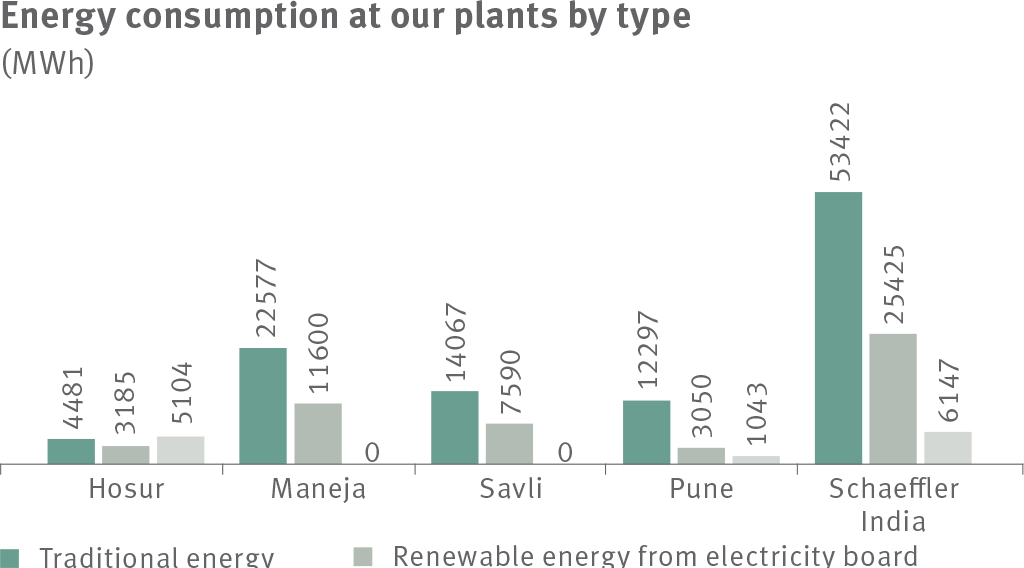

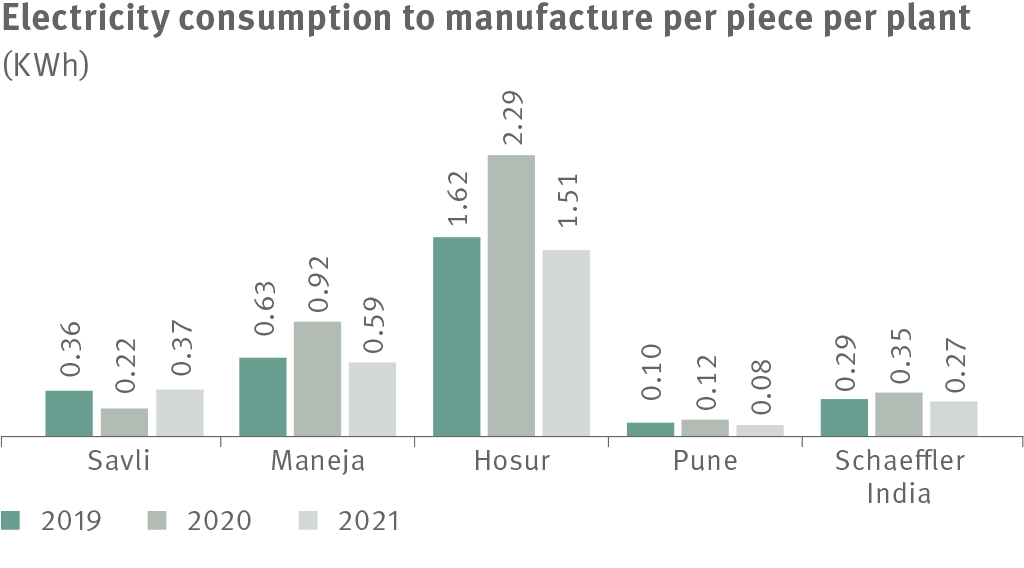

As a consumer of fossil fuel based power, we recognise the climate-related risks associated with our business activities. We understand the implications of our energy consumption, both in terms of its cost to the natural environment as well as cost to operations. We are taking mindful steps to decarbonise our operations and move towards renewable energy. Our energy policy predominantly straddles efficient energy use, implementation of innovative projects to reduce energy demand and proactively embracing renewable energy. We have deployed state-of-the-art and energy-efficient systems and practices across our operations and moved towards renewables.

Renewable energy capacity own generation / power purchase agreements

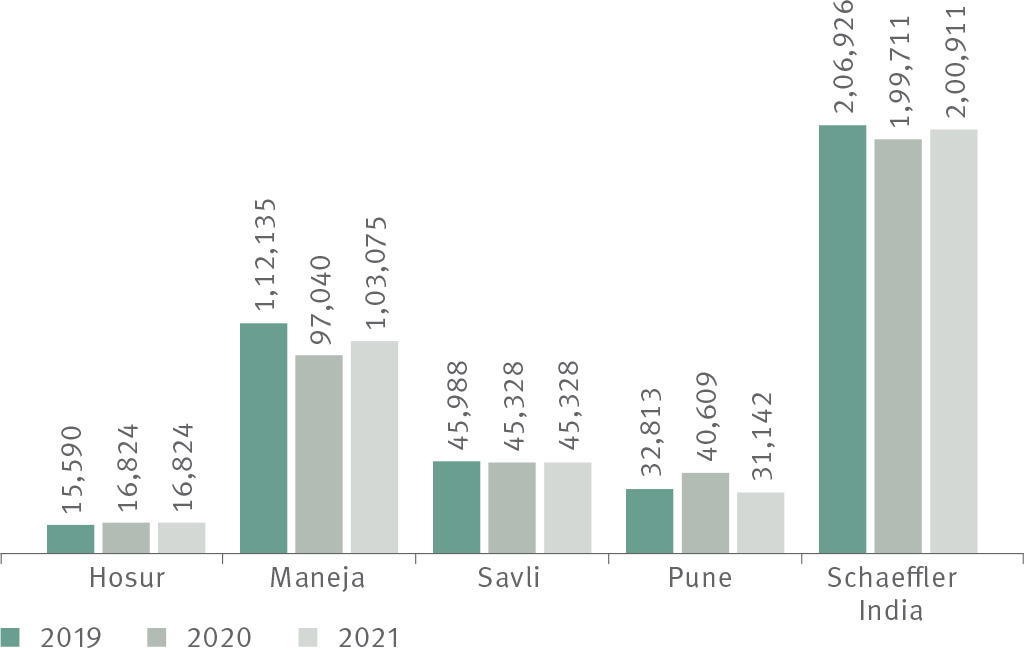

Energy used

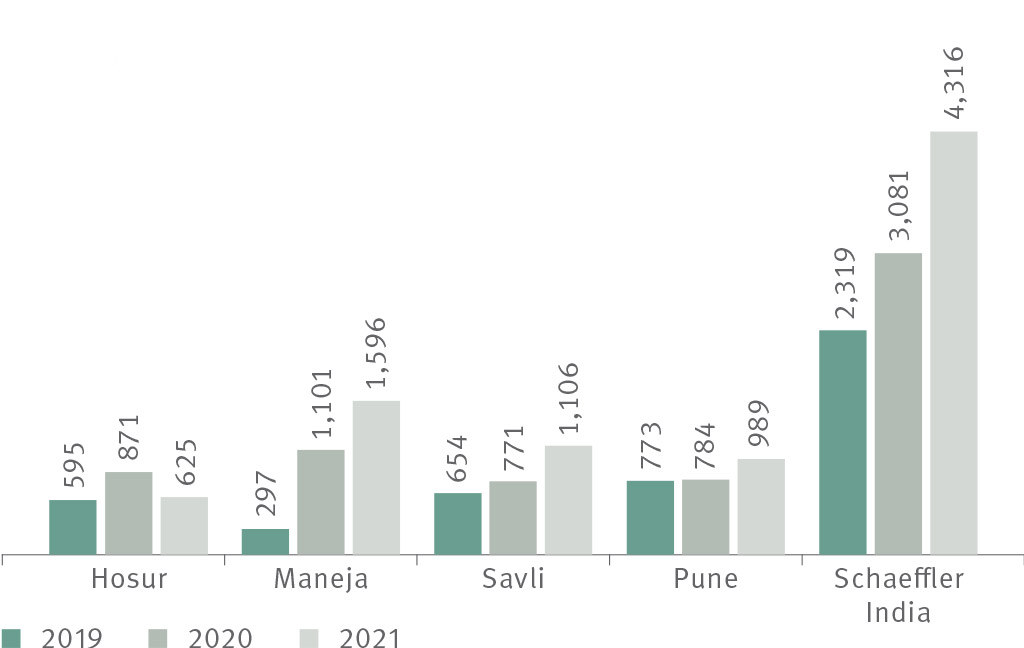

Renewable energy used from own generation or PPA

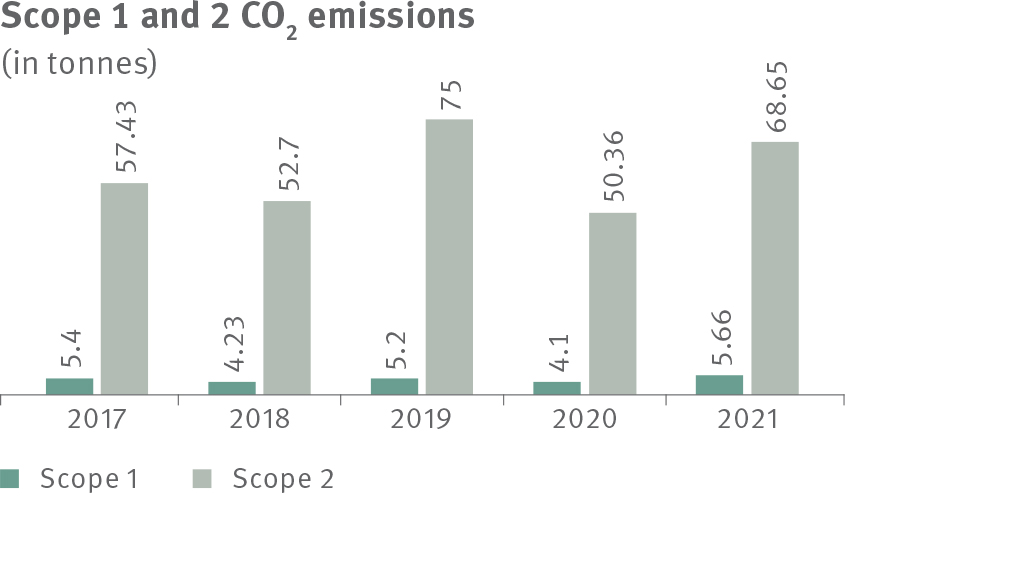

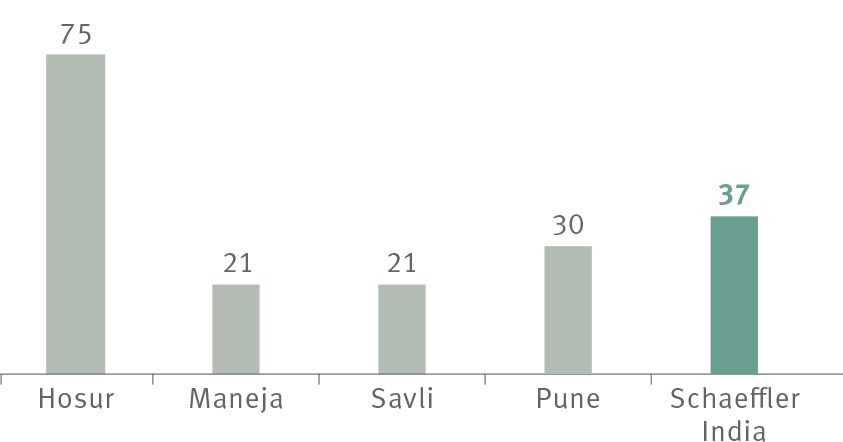

Scope 1 and Scope 2 emissions

Key initiatives undertaken in 2021

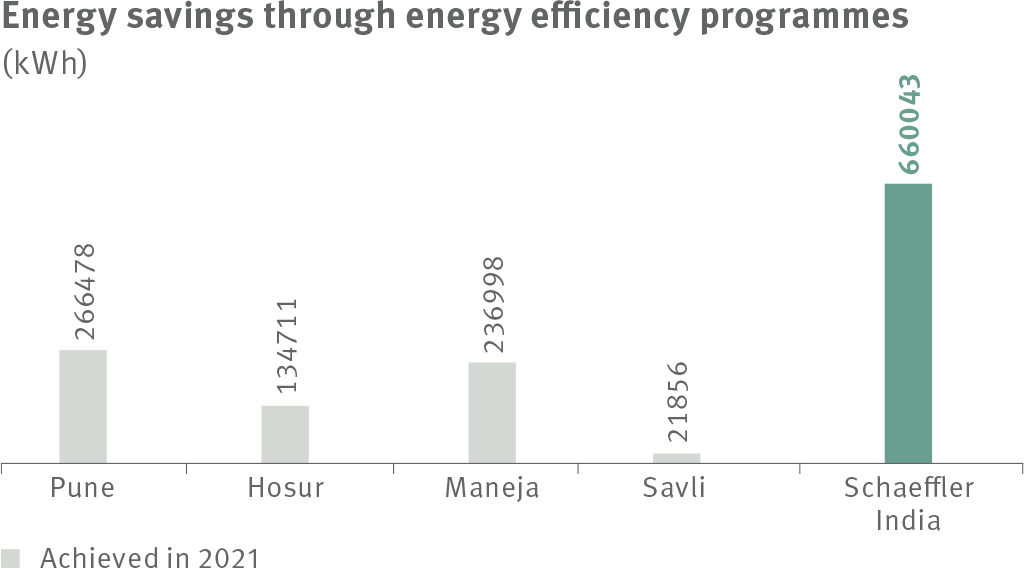

While our energy consumption, in terms of absolute numbers, saw an increase due to a surging demand, we continued our shift towards cleaner fuels, and made gradual efforts in reducing our consumption.

Focus area 2022

| Initiative | Plant | Energy savings per annum (MWh) |

|---|---|---|

| Replaced MH medium bay light with LED light in old RHF area | Savli | 25.63 |

| Installed insulation jacket to ITF washing machines | Pune | 6.39 |

| Lighting changed at the outer periphery from 250 W sodium-vapor to 80 W LED | Hosur | 59.33 |

| BB 10 machine GW wheel of 22 KW motor replace with 18.5 KW motor | Pune | 13.75 |

| Digital addressable lighting interface light system installed for Hall 1 | Pune | 126.95 |

| Heater less vapouriser for LPG bank used for replacing electrical heater base vapouriser | Hosur | 75.44 |

Globally, there is a clear transition to cleaner energy and fuels with continued growth in demand, spiralling prices, and increased consciousness of impact of fossil fuel on the climate. Over the last few years, we have been working on our energy mix to ensure energy sufficiency for the future. As part of our long-term plan, we are expanding our infrastructure to produce adequate green electricity to meet our energy demand.

Renewable capacity

Renewable energy capacity

Added during 2021

Additional planned over 2 years

Renewable energy share

(%)

Careful sourcing as well as innovative and efficient use of water, form parts of our water stewardship approach. Several water conservation measures were initiated at our plants to help us manage our available and sourced water efficiently. This includes changing of pipelines to achieve reduced flow for domestic purpose, reused treated water for process to reduce topping, usage of treated RO reject water used for fire hydrant, and pedal operated valves for hand washes, urinal flush, among others.

Renewable capacity

Recycled and treated water used in operations and domestic purpose

Additional planned over 2 years

Reduction in freshwater usage

Key initiatives undertaken in 2021

Focus area 2022

Water consumption

(m3)

We generate waste in different forms and quantities during our production process and through packaging of our products. Our hazardous waste primarily consists of effluent sludge or chemical sludge and used oil.

To manage these, we have implemented various efficient waste management initiatives, which takes into account environmental impact, social effects and commercial viability. We dispose our hazardous waste at a government‑approved central landfill, while our non-hazardous waste is primarily recycled by sending it to authorised recyclers.

Waste generated

Hazardous waste generated

Packaging material recycled are optimised and converted into returnable packagings

Waste generation

(tonnes)

Key initiatives undertaken in 2021

Focus area 2022