Our Industrial division is the market leader in bearing solutions, and we proactively shape the future via the increased use of new digital and mechatronic technologies.

Revenue

12.4%

Schaeffler India Loyalty Index

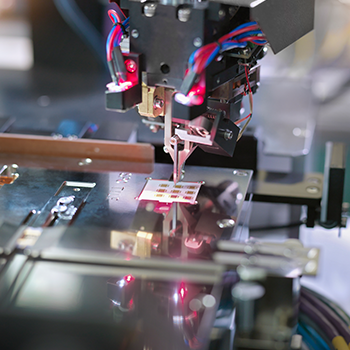

We have two strong and mature bearing manufacturing plants in Vadodara, driving a significant amount of localisation initiatives. We have invested in a new R&D centre for industrial bearings at the Maneja (Vadodara) facility embedded in the manufacturing location, which is currently in the nascent stages of development. Currently equipped with testing and validation competency in its early stages, there are plans to scale up the competencies as the project progresses.

The centre's ultimate goal is to develop new, innovative solutions for industrial bearings that will improve performance and reliability. With a focus on research and development, the centre will play a critical role in advancing the field of industrial bearings, and we look forward to seeing the advancements that will come as a result of this exciting new project.

The Indian government is committed to boosting economic growth through infrastructure expansion. Budget 2023–24 increased capital investment outlay by 37.4% with the highest ever railway capital outlay of ` 2.4 lakh crores. This is expected to drive demand and place our industrial business on a high growth trajectory.

Budget 2023–24 capital investment outlay*

Green hydrogen is set to play an important role in India’s ambition to reach 500 GW of non-fossil fuel capacity by 2030 and in developing energy storage solutions that could potentially replace lithium-ion-based batteries. Schaeffler India’s technological capabilities place us well along the green hydrogen value chain to help facilitate India’s green transition.

Budget 2022-23 outlay for green hydrogen*

*Source: Government of India

Developing smart, sustainable solutions

Steel production is a critical driver of economies worldwide, but it also accounts for a significant portion of global emissions and contributes to 8% of CO2 pollution. A way to facilitate the transition to a greener future is to extend the lifespan of steel-based bearings.

Our bearing refurbishment centre in Jamshedpur plays a significant role in facilitating this transition. With its strategic location near our customers, we can efficiently repair bearings used in continuous operating processes across a wide range of industries, including mining, metal and minerals, pulp and paper, railways, and the power sector.

By providing bearing conditioning services, we assist our customers in saving significant time and cost while also making a positive impact on the environment.

Refurbishment extends the lifetime of bearings by

Despite facing inflation and supply chain bottlenecks, particularly with our imported products, we persevered to maintain a healthy earnings profile through our strategic focus on localisation. Although our wind segment tapered off towards the second half of the year due to a global slowdown, our key segments in railway and mining continued to show resilience, and we remain optimistic about our long-term outlook.

On the operational front, we made significant strides in future-proofing our business through digitalisation and automation initiatives. We implemented the Toyota Production System, targeting operational efficiency, safety, quality, and productivity. This year, we gained invaluable insights into quality management and safety, which will continue to be instrumental in our growth and success.

With our robust portfolio, technical and operational expertise, and expanding capacity, we are well-positioned to harness the potential of India's growth story."

Harsha Kadam

Managing Director & CEO,

President – Industrial