Schaeffler India acknowledges the responsibility of businesses to help address the world's most pressing issues such as climate change. We have taken on the challenge of the Schaeffler Group to become climate neutral by CY40, through the implementation of innovative solutions and technologies.

We implemented the following initiatives:

Emissions avoided

Trees saved

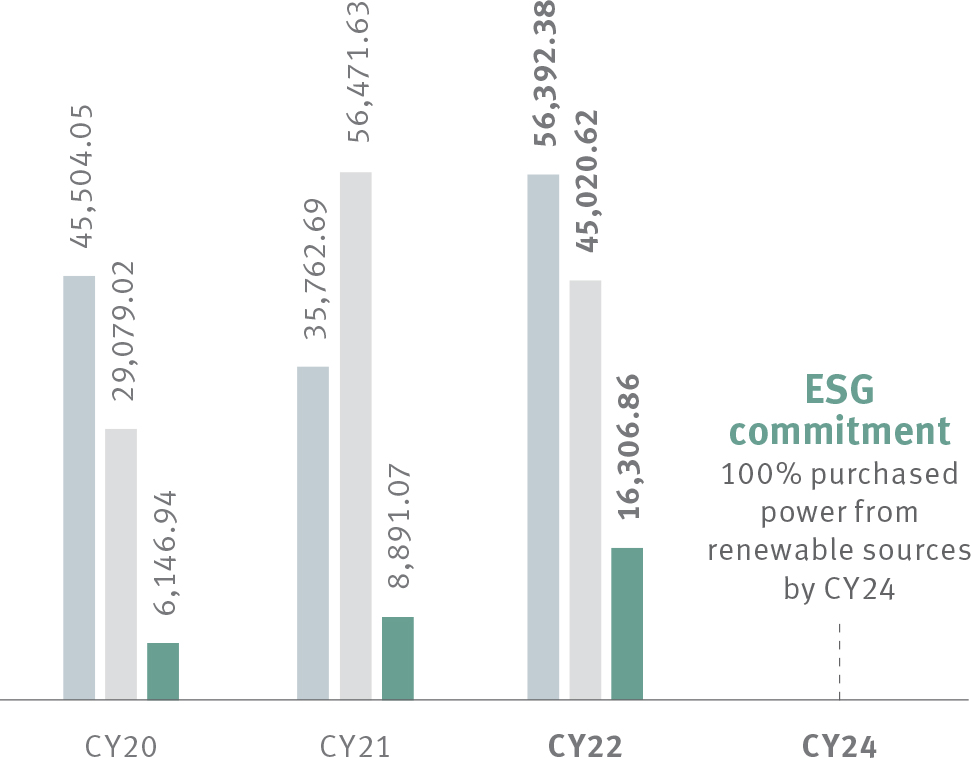

We acknowledge the impacts of our energy consumption both in terms of its toll on the environment and its cost to our operations. We are taking proactive steps to decarbonise our operations and transition to renewable energy sources. We target to achieve 100% renewable power consumption by CY24.

Various steps have been initiated to reduce carbon footprints with an aspiration to attain carbon neutral production by CY30 and be carbon-neutral by CY40.

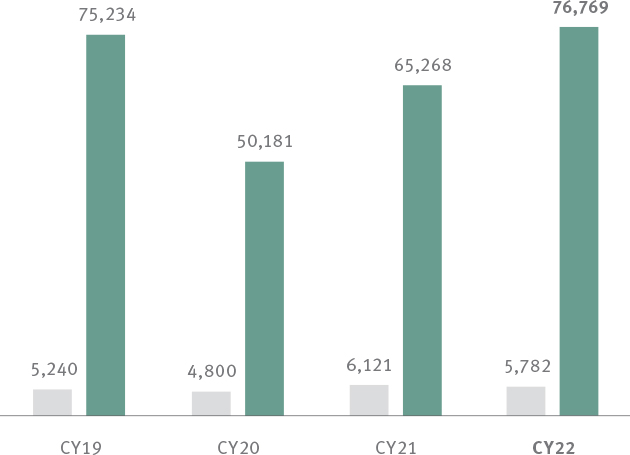

With the baseline of CY19, we undertook various initiatives to reduce Scope 1 and Scope 2 emissions by implementing energy efficiency projects. Our efforts led to 1.31 GWh energy savings which neutralised 1,034 tonnes of Scope 1 CO2 emission. Renewable energy contributed to 44% of energy consumption through our existing projects and by purchasing renewable energy through PPAs. Overall, we neutralised 12,500 tonnes of Scope 2 CO2 emissions in CY22.

While our energy consumption, in terms of absolute numbers, increased due to surging demand, we continued our energy-efficiency initiatives and made gradual efforts to reduce our consumption.

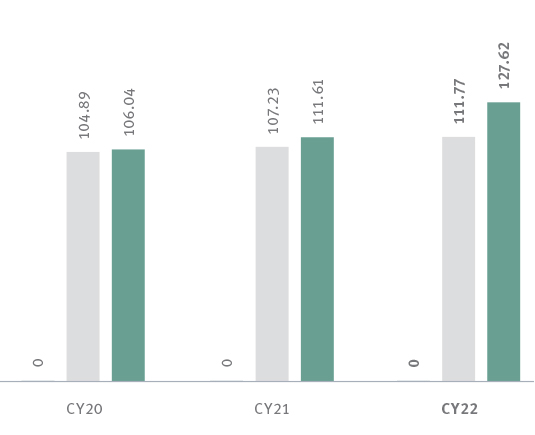

Energy intensity

(Total energy consumption/turnover in rupees)

We have been constantly working on purchasing green energy at our locations. We have signed a hybrid energy (solar and wind) Power Purchase Agreement (PPA) for Maneja (Vadodara) of 2.55 MW which will contribute 34% of its overall consumption which started from August 2022. As for Savli (Vadodara), we have a hybrid energy PPA for 1.8 MW, which will contribute 35% of overall consumption will begin in CY23. Additionally, our facility at Pune have signed a PPA of wind energy for 5.1 MW.

Average solar power generation per month

Contribution of renewable energy

| Initiative | Plant | Energy savings per annum (MWh) |

|---|---|---|

| Cold washing media for post washing from Seal Quenching. | Hosur | 678.91 |

| Installation of Inverter and pressure transducer in coolant supply system. | Maneja (Vadodara) |

95.94 |

| Installation of emulsion pump with Inverter and pressure transducer. | Maneja (Vadodara) |

57.70 |

| Heat recovery by jacket installation on washing machine. | Pune | 11.72 |

| Reduce energy consumption by installing top cover on salt bath. | Savli (Vadodara) |

280.89 |

| Reduce power consumption in pre and post washing drying operation using waste heat. | Savli (Vadodara) |

183.33 |

Total energy savings in CY22

In CY23, our Hosur location is planning to install its solar rooftop panels of capacity 1.5 MW and Savli (Vadodara) will start receiving hybrid power which will increase the overall share of renewable energy to 56%.

Our water stewardship approach is characterised by careful sourcing and the innovative and efficient use of water. Several conservation measures are implemented in our plants to optimise our available and sourced water, such as replacing old pipelines, reusing treated water for processes to cut down on topping, using treated RO-rejected water for fire hydrants, and installing pedal-operated valves for operational usage.

We are aligning to achieve the group target of a 20% reduction in freshwater withdrawal by CY30 with a baseline of CY19. We are implementing various water-saving projects and are reusing the treated water for domestic and production purposes to reduce freshwater intake. The projects implemented in CY22 have contributed more than 50% of the CY30 target.

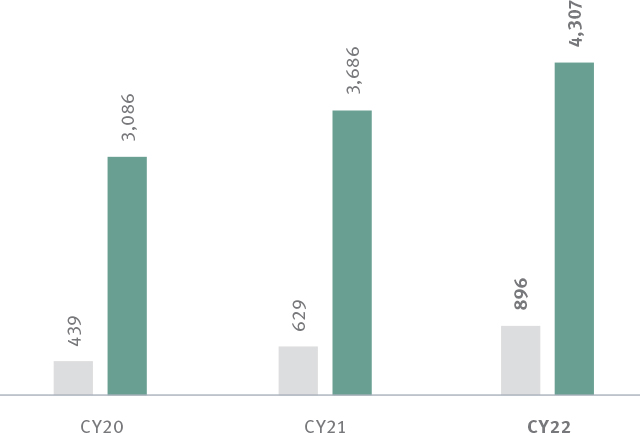

Water intensity

(Water consumed/turnover in rupees)

Rainwater harvesting capacity by recharging groundwater

Recycled and treated water used in operations and for domestic purposes

India is facing increasing water scarcity due to population growth and industrialisation. Jal Samruddhi is our initiative to tackle these issues through natural resource management in two villages in Khed Taluka, Pune. We aim to develop drought-resistant villages and increase agricultural income by 20–30% by CY23 for 2,500+ citizens.

Beneficiaries

Water harvesting capacity created

We intend to sustain our efforts toward the conservation of water by executing structured projects across all our locations. In continuation with CY22 measures, we have started implementing the water saving initiatives which will save around 10t m3 water through the installation of water saving faucets and re-use of waste water.

We adhere to the three R principle: Reduce, Reuse, and Recycle. To manage our waste, we implement various efficient waste management initiatives that consider environmental impact, social effects, and commercial viability. We dispose our hazardous waste at a government-approved central landfill, while our non-hazardous waste is primarily recycled by sending it to authorised recyclers.

At Schaeffler, circularity is one of the action fields in our execution program. We are working on continuous improvement in reducing waste generation which has led to us achieving 82% recycling of the waste generated in CY22.

Waste regenerated

Waste Recycled

Waste diverted from landfill

We are working on converting the disposable hazardous waste generated from treatment facilities to a reusable co-procession material in the cement industry which will enable us to achieve zero waste to landfill by CY25. The pilot project has already been started at Savli (Vadodara).

Material yield is one of the major areas we are working to reduce the scrap from the production process and automotive plants will take up the target of achieving 3% material yield by CY25.