We are committed to reducing our environmental footprint by constantly looking for ways to deploy our resources more efficiently. Adoption of renewable energy across our facilities is a key enabler of energy efficiency at Schaeffler India. We are developing renewable energy (wind and hydropower) across our facilities as well as innovating to develop products that help make the world greener.

Capital

SDGs

We ensure that every member of our organisation strives towards reducing energy and water consumption, minimising waste and reducing energy emissions. This is done by driving internal awareness campaigns and modifying SOPs to incorporate sustainable practices.

Since 2018, we have been consolidating our warehouses and distribution centres to drive all-round efficiency. This exercise has led to reduction of over 1,27,600 kms of truck movement and 84,216,000 gms of CO2 emissions per litre of diesel over the past three years.

We aspire to achieve climate neutrality across all our plants by 2030 and have progressed well towards this goal during FY20.

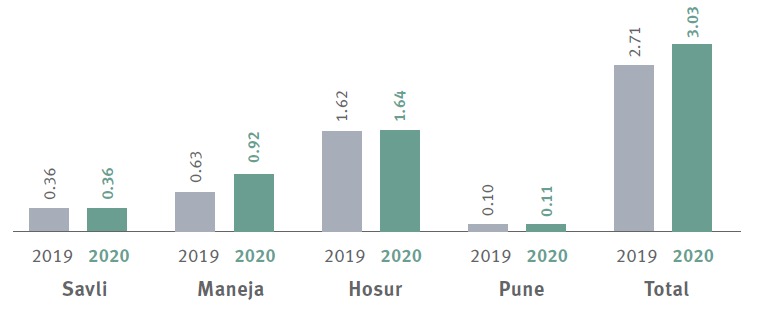

Energy consumed in per piece production

(KW)

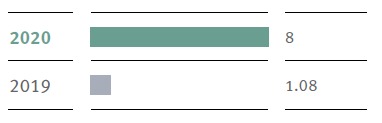

Renewable energy produced

internally/purchased from third party

(%)

Renewable energy from

electricity board

(%)

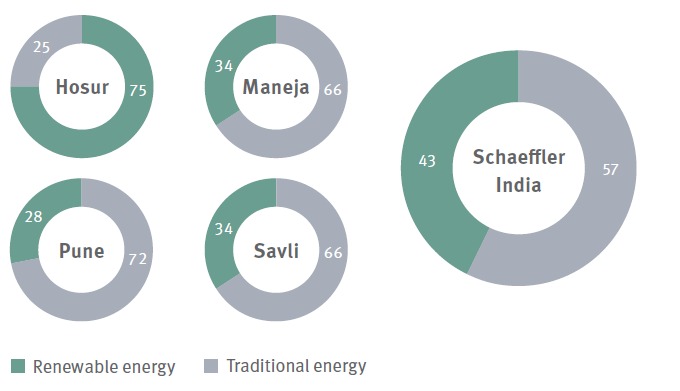

Renewable energy vs. traditional energy mix

(%)

Initiatives taken during the year to optimise energy consumption

We have undertaken several initiatives that facilitate clean technology, energy efficiency, renewable energy and more.

For Hosur plant, we purchased renewable energy of 5 MW generated from solar panels. This comprised 50% of the plant’s overall consumption and lead to neutralisation of 4185 tonnes of CO2.

Every location focuses on carrying out energy efficient projects and achieve energy savings of 429 MW.

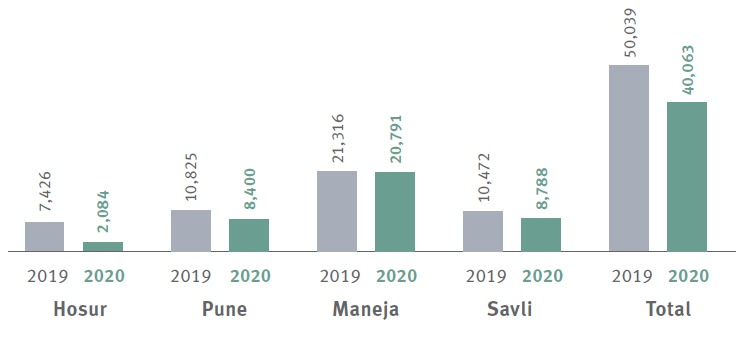

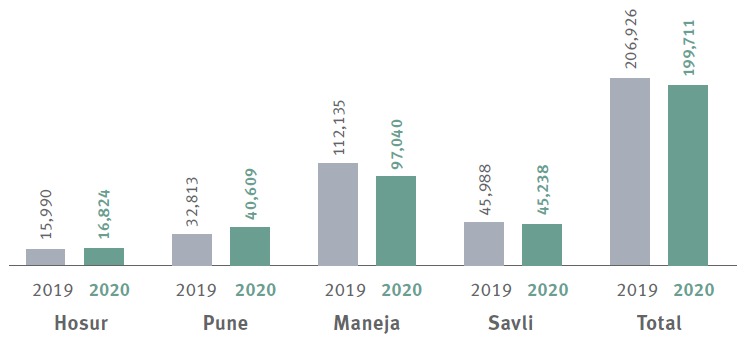

Scope 2 CO2 emission

(in tonnes)

Initiatives taken during the year to

optimise

water consumption

Water consumption

(m3)

Note: water consumption has gone up in Pune and Hosur in 2020 post maintenance activities due to COVID-19.

Initiatives taken

In 2016, we implemented several steps to reduce emissions under Scope 1, 2 and 3 at the plant. Neutralising Scope 2 carbon emissions i.e. from electricity was a key objective. In 2020, the plant’s EHS coordinator found an efficient solution – procuring solar energy produced by third party. This would not entail any major investments that come with high RoI of over 4.5 years. The team comprising EHS coordinator, energy coordinator and plant purchaser identified the best supplier fulfilling Schaeffler’s terms and conditions after undertaking thorough due diligence.

In 2020, the plant signed an agreement to procure solar energy of ~5 MW.

Achievements in 2020

Tonnes of carbon neutralised

Saved electricity cost worth

Share of solar in total energy consumption