We adhere to the Climate Action Plan developed by our parent organization. It empowers us to efficiently utilise resources and limit our carbon footprint across the value chain. With an emphasis on climate neutrality, energy efficiency and circularity, we are initiating responsible transitions.

Our science-based targets have been verified by SBTi and aligns with the pathway set by the Paris Agreement.

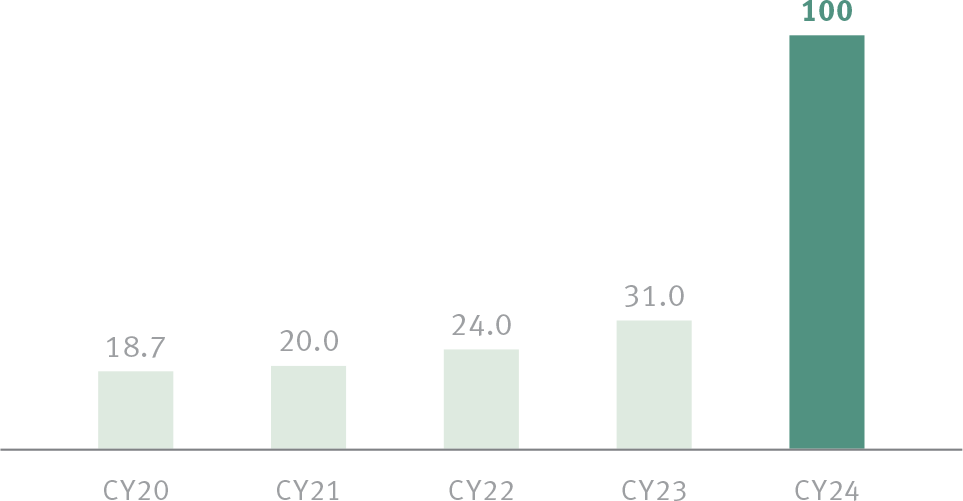

Renewable energy plays a crucial role in our decarbonisation strategy. We have set up about 1.722 MWp of rooftop solar at our Talegaon and Savli plants. We also have Power Purchase Agreements (PPA) with renewable power generators. In 2024, iRECs were purchased to offset the energy consumed by Schaeffler India and achieved 100% renewable energy.

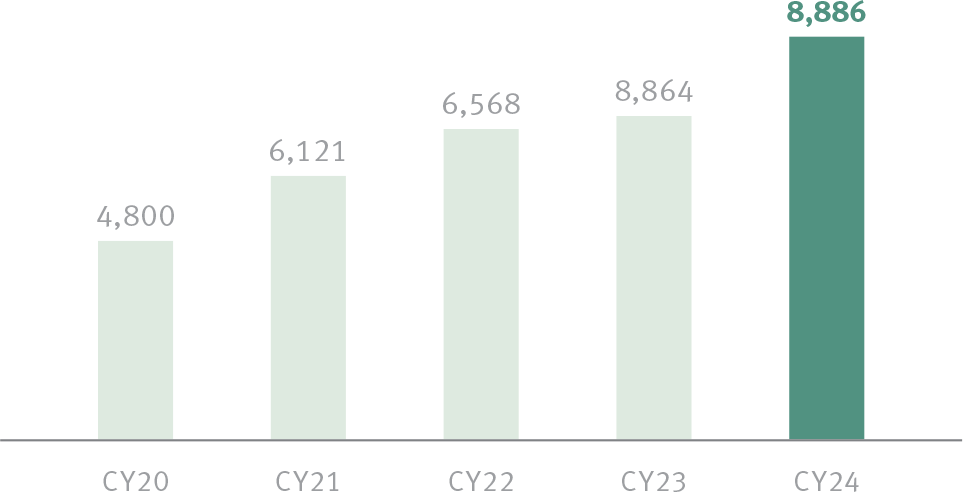

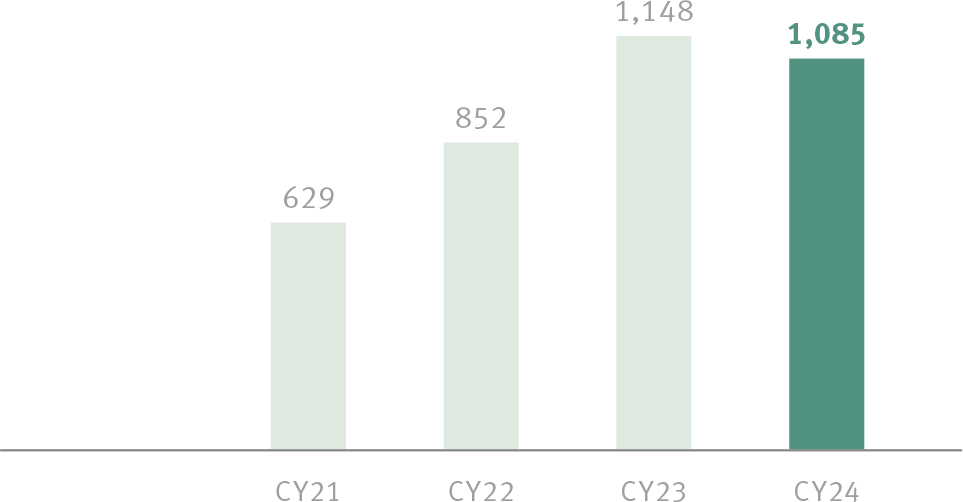

GHG emissions averted

At Schaeffler India, we are undertaking efforts to ensure energy-efficiency across our operations. We have adopted multiple initiatives such as Old Chiller replacement, Nova Machine Motor Replacement, Replacement of old Compressors, Bell furnace cover installation to save waste heat due to radiation, reduce air pressure in Jupiter machine, Barrel Heater Jacket Installation on IMD Machine, Exchange Broach Hydraulic motor to improve energy efficiency and reduce emission.

Energy efficiency projects of 906.31 MWh have been completed in 2024.

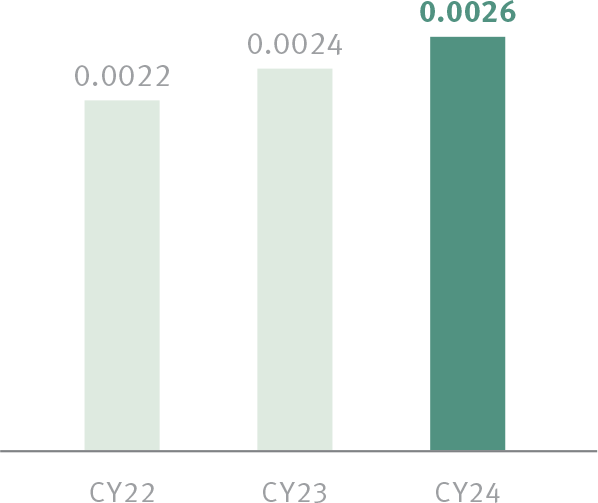

Energy efficiency projects achieved against a target of 662.7 MWh

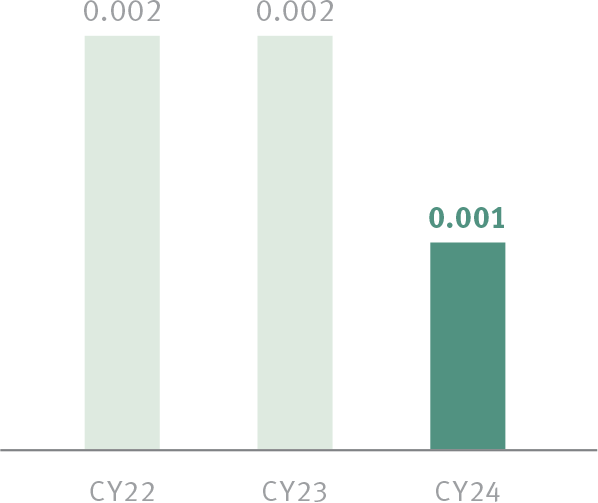

1 Scope 2 emission for CY 2024 is calculated considering usage of renewable energy and purchased International Renewable Energy Certificates (iREC) to compensate existing emissions

Targeted interventions to ensure energy efficiency

One of our manufacturing facilities sought to

reduce energy consumption and improve process

efficiency across various operations.

To achieve

this, three key initiatives were implemented:

The Jupiter Machine was connected to a dedicated

high-pressure (6 Bar) compressor leading to

efficient use of compressed air.

Annual energy savings

Implemented the Bell Hardening Furnace with temperature-based interlocks, individual blower controls and an auto-cutoff timer to improve inefficient heating and cooling cycles.

Annual energy savings

Targeted interventions for improvement of energy efficiency in compressed air generation by replacement of old Air Compressors with new compressors demonstrate the potential for substantial energy savings and process improvements through simple yet effective solutions.

Annual energy savings

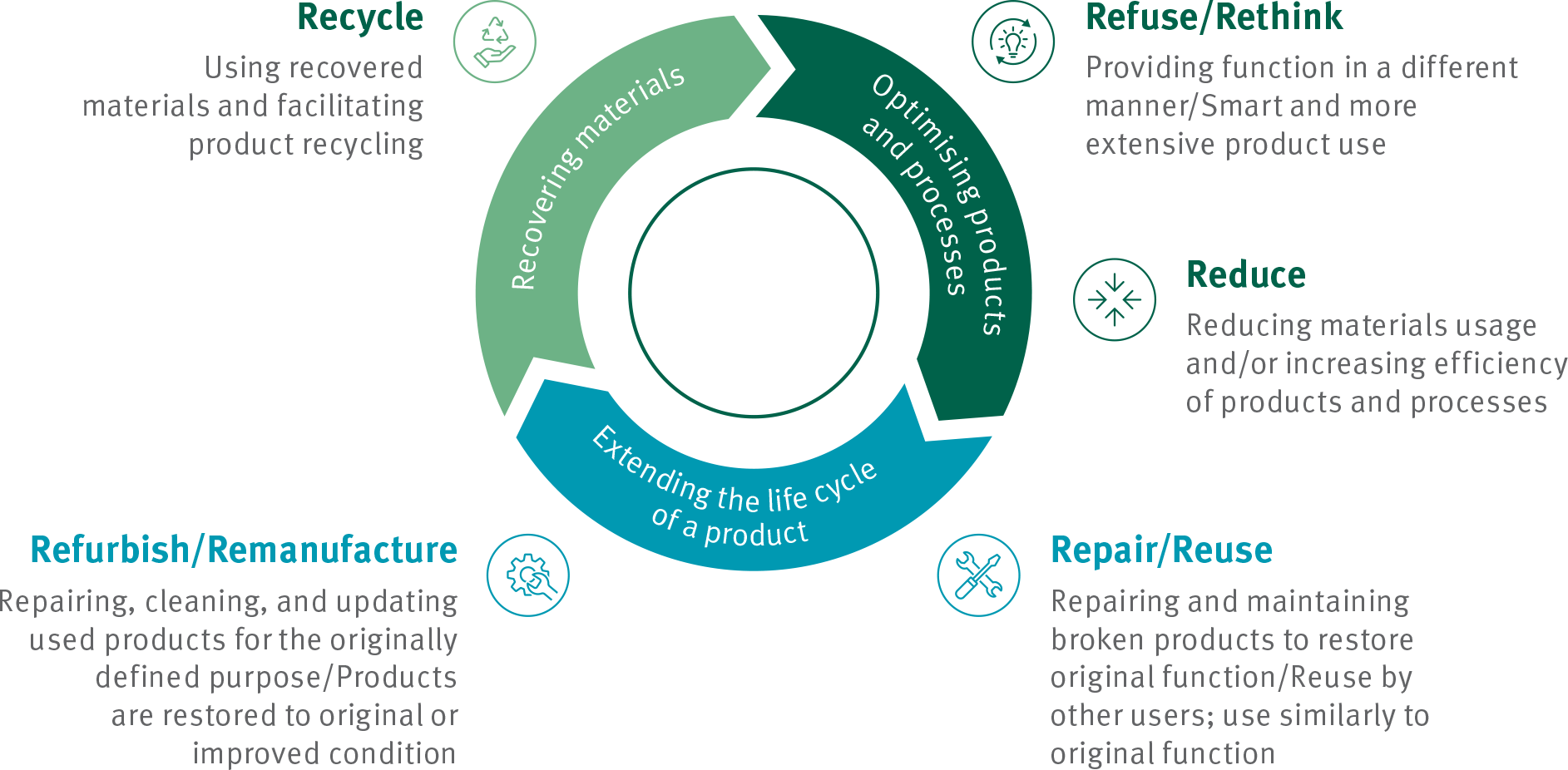

We strive to limit the carbon footprint of our products, from design to production. As a result, our circular economy strategy focuses on reuse, repair, refurbish, remanufacture and recycle. We recycle all our metal scrap, plastic packaging scrap and other scrap through authorised recyclers or re-processors. Further, plastic waste generated during the moulding process is recycled back in the process. Hazardous wastes like used oil and waste oil are sent to CPCB authorised re-processors. Efforts are also made to co-process other hazardous wastes by engaging with cement companies.

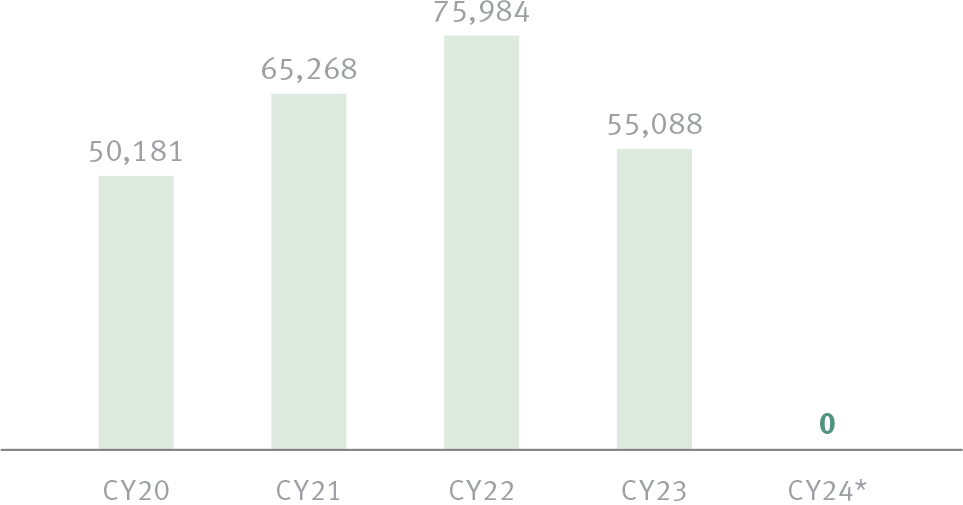

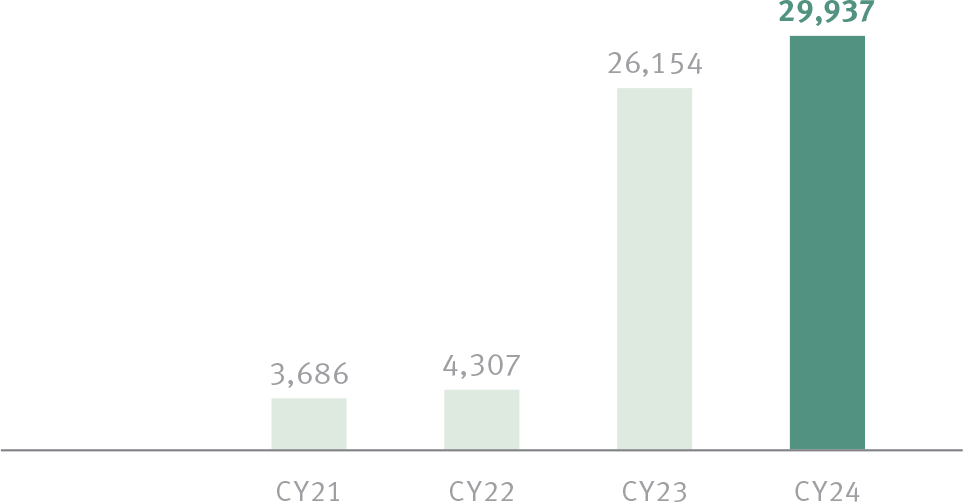

Hazardous waste generated

Hazardous waste recycled

To manage waste, we implement various waste management initiatives that consider environmental impact, social effects and commercial viability. Since November 2024, all types of hazardous waste generated in the plants, such as ETP Sludge, Grinding Sludge, residue or waste containing oil, used oil and discarded containers are sent to recycler or re-processor or for co-processing. It is expected to result in Zero Waste to Landfill by 2025.

Driving sustainable waste management

Schaeffler India is transitioning its hazardous

waste management approach, from traditional

landfill and incineration methods to an innovative

alternate fuel conversion process. By partnering

with a new service provider, we transformed our

waste disposal challenges into eco-friendly

opportunities. This MoEF and CPCB (Ministry of

Environment - Forests and Central Pollution

Control Board) endorsed solution not only helps

to deliver superior grade alternate fuel but also

significantly diminishes environmental impact.

It also addresses concerns related to

single-source dependence and 13-14%

year-over-year cost increase.

Reduction in annual disposal costs

Annual savings

CO2 emissions saved

Reason for Increased waste: Due to data maturity issues, more categories have been added.

Major portion of non-hazardous waste constitutes of metal and casting scraps which are recycled in the steel mills and foundaries.

Water consumption is kept under check by adopting the projects like the treated STP water usage after demineralisation, optimising cooling tower daily blow-down water quantity, Treated water reuse in de-oiler and poly dosing tank.

We reduced power consumption of SRU by processing high salt concentrated Dipping Basin Water and have added this water to SBM instead of DM Water. This has helped to reduce DM water (90 KL per annum) and 168 MWh electricity consumption per annum.

Water conservation through STP water recycling

We installed a Scale and Bio Remover (SBR) for Non-Chemical Treatment for a

Cooling Tower. The green technology saves water as well as electricity. The SBR

system is connected to the cooling system or the cooling tower internally,

resulting in swift installation. A side stream filter is also integrated into the

SBR system. The reaction tank is connected to the cooling tower via a circulation

pump and the water is circulated from the cooling tower basin to the reaction

tank and back to the cooling tower though an integrated side stream filter.

Reduction in operational cost

Water conserved through waste water recycling